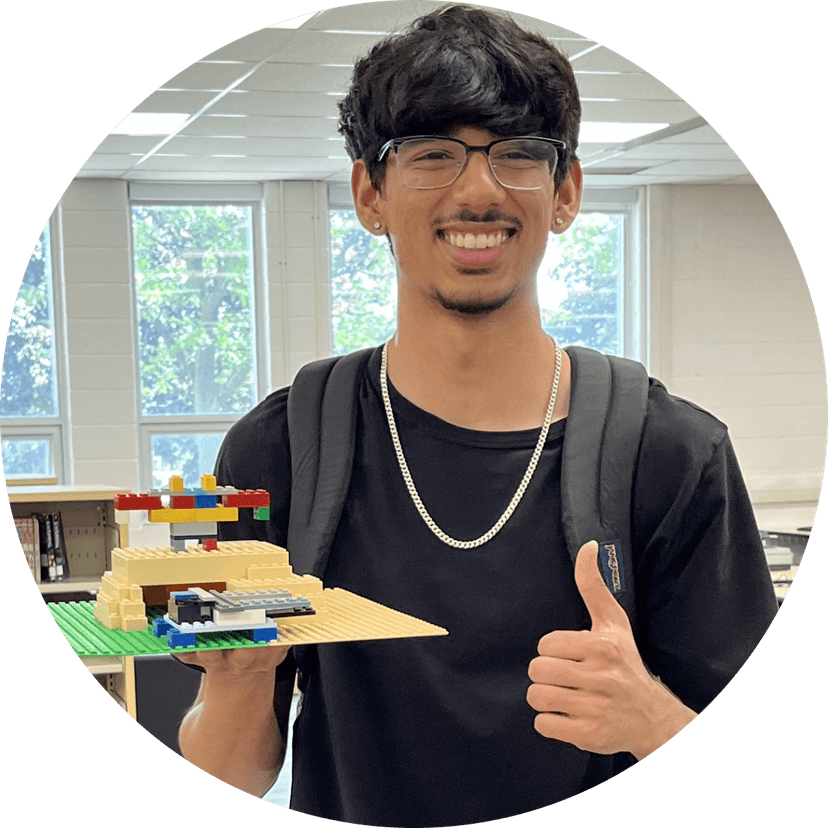

Jobanpreet Natt

TECHNICAL EXPERIENCE

PROJECTS

Autonomous Robot Piano Player

C, Robotics, Feasability Analysis, Collaboration

The robot's (Happy Keys) mechanical design features a lightweight structure, intuitive controls, and a stable base. The construction utilized Lego pieces, 3D-printed and laser cut components, facilitating easy alignment and broadening the range of playable songs. Happy Keys met all specified engineering requirements, including key accuracy, cost efficiency, and speed. The robot played pre-programmed songs with precise timing.

Magnetorquer Winding Mechanism

SOLIDWORKS, 3D Printing, Rapid Prototyping

Maintaining an upright position is crucial for a satellite to gather accurate data and take high-quality images. Magnetorquers are solenoids that allow the CubeSat to leverage the earth's magnetic field and correct its attitude. According to Lenz's Law, the emf is proportional to the number of turns in the coil. This winding mechanism allows the team to manufacture solenoids with high levels of precision and accuracy to achieve optimal and predictable results.

Endless Runner Game

3D Printing, Machine Shop, R&D, Rapid Prototyping, Reporting

For our ME100 project, my team and I built an endless runner game inspired by subway surfers, but in real life. The project required us to produce prototypes and design complex systems within a short deadline. This included 3D-printed pulleys to translate the forces, a wooden chassis, and a treadmill to simulate an infinite track. We created a proposal for our final product and a report of choices, problems, solutions, and feasibility analysis.

Hall Effect Potentiometer

R&D, EasyEDA, Soldering, 3D Printing, I2C

Created circuit schematics for PCBs with EasyEDA as well as a 3D printed housing with SOLIDWORKS in accordance to the physical dimensions of a Dualshock4 controllers' joystick. Implemented a hall effect sensor that detects rotating magnetic fields and acts as a potentiometer to minimize electronic noise and interference caused by wear and tear of physical potentiometers, thus massively increasing longevity of the controller.

Surgical Arm

Python, Arduino, Intgrated Circuits

During this 36-hour Hackathon, my team and I built a single-axis robotic arm with a pincer at the end. The joints were controlled by the user moving their own arms through a camera running OpenCV (open computer vision). The chassis was built with popsicle sticks since they were easily accessible, strong, and lightweight. The L239D was used to control the DC motors and the ULN2003 was used to drive the 28BYJ-48 stepper motor. This provided good experience with robotic software development and integration, as well as Arduino microcontrollers. (Only 500mA were availible, although motors are weak, motion is visible)

Autonomous Piano Player

Motors/Motor Control, Basic Analogue Circuits, BreadBoards, Python

For the MakeUofT Hackathon, my partner and I failed to create an autonomous piano playing mechanism. Two 28BYJ stepper motors and two Nema-17 stepper motors were controlled by an Arduino running pyfirmata2 to play a song in C-Major. The user must upload a .wav file into the software and it will use Fourier analysis to break up the sound into its constituent frequencies. The notes are then mapped to a stepper motor that turns in the direction of the key. We were constrained by the availible voltage and current, so although the code is complete the project is unfinished. See Devpost button below for code.

Airplane Shooter Game

HTML, JavaScript, CSS

My first experience with object-oriented programming was making this Airplane Game where the objective is to destroy the other plane. The game uses the users' keyboard input to move the planes around and shoot. Although simplistic, it was an informative introduction to performance optimization, event handlers, and objects.